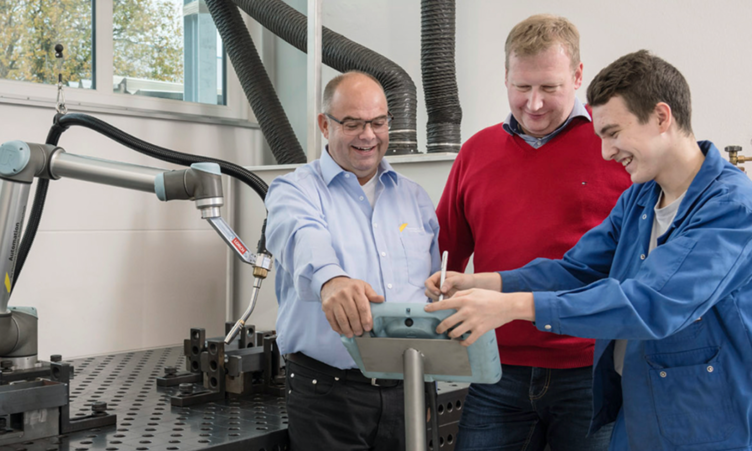

Efficiency increase

The automatic synergy setting produces perfect weld seams quickly, easily, and reliably, without any teach-in or transmission errors. This saves time and money while also ensuring consistently high quality of the welding work.

Maximal work safety.

M-Pro series products effectively protect your welding professionals while ensuring highest safety at work with their three special features:

1. Angled torch connection

2. Double gas cylinder safety device

3. Rolling lock total stop roller

Robust housing.

The M-Pro housing is extremely robust and mobile thanks to its sturdy handles. This makes it ideal for use in a workshop. The top of the case also makes for a perfect storage surface.

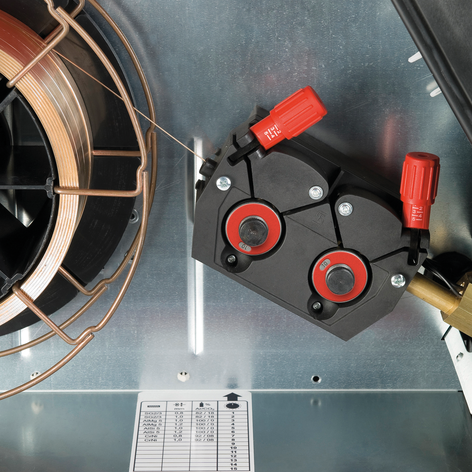

Interior lighting.

Interior lighting improves visibility for wire threading in the easily accessible wire feed compartment of the M-Pro series. This allows the welder to work well at all times, no matter how bright or dark their environment is.