Make your team stronger.The new Lorch Cobot Welding World for customised complete solutions.

Cobot welding: Simple automation for any production process.

The flexible cobot welding solution from the market leader. Efficient, economical and future-proof.

Cobot welding, or collaborative robot welding, is the ideal automation solution for companies of all sizes and is especially ideal for small to medium batch sizes.

The welder remains in control of the system, while the cobot executes precise instructions. This collaboration increases productivity and quality, reduces the workload for the welder and makes the workplace more attractive. The investment costs are significantly lower than for conventional automation solutions such as industrial robots, which are often less flexible.

Would you like to learn more about cobot welding? Our free guide offers valuable insights into the applications and advantages.

First-class welding technology and maximum service.

A world for winners: everything works together – the result is top performance.

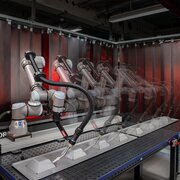

Lorch Cobot Welding World provides an easy introduction to welding automation for small and medium-sized businesses. With our MyCobot system kit, we offer you customised complete solutions that can be easily integrated into your workflows. Intelligent software, perfect processes and an international partner network make all the difference to your project.

- Consulting: Transparent consulting based on your workflows and objectives.

- Customised complete solution: Perfectly coordinated components for intuitive operation and efficient working.

- Financing: Attractive offers ranging from leasing to financing your Cobot welding system.

- Layout and assembly: Reliable layout and integration until your system is up and running.

- Training and instruction: Get productive right away thanks to easy-to-understand training on operation and functions.

- Customer service: Our qualified cobot partners are available to assist you with a wide range of services.

Flexibly combine all components.

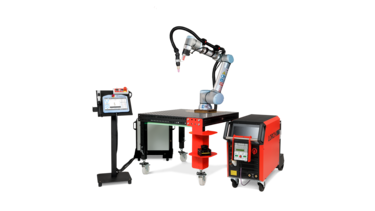

MyCobot system kit

The MyCobot system kit offers an innovative solution for welding automation that is tailored to your specific requirements. Thanks to the plug-and-weld principle, the modular system kit enables flexible and customisable welding solutions. With myCobot, you benefit from an individually configurable solution that offers maximum efficiency with minimum risk. Thanks to its ease of use, fast amortisation and reliability, myCobot not only increases the productivity of your welders, but also that of your entire company.

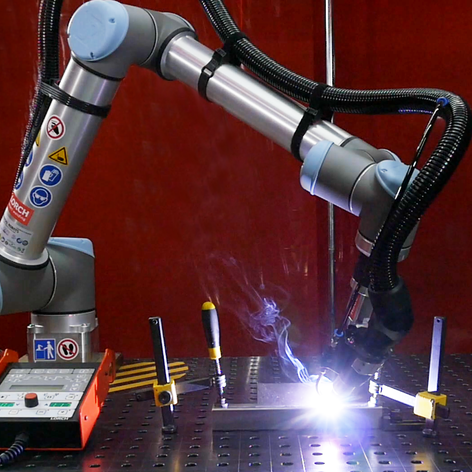

The powerful UR10e cobot from market leader Universal Robots is the right team player for every challenge. In combination with our intelligent Lorch Cobotronic software and the flexible features within the modular system, this multi-talented device offers a forward-looking solution for your welding tasks. The UR10e supports your team by taking on monotonous and stressful tasks. This minimises the risk of accidents and increases productivity at the same time.

Your individual automation solution.

MIG-MAG - Cobot

Optimise your welding (processes) with the Lorch Cobot Welding Solution. Increase productivity, reduce waste and ensure quality with automated welding technology. A future-proof solution for consistent results and efficient use of your resources.

TIG - Cobot

With the TIG cobot from Lorch, you get precise and clean welding results. Thanks to simple manual guidance and flexible safety technology, you can weld efficiently and without restrictions. The cold wire feed ensures maximum accuracy.

S-RoboMIG XT series

The S-RoboMIG XT series allows you to achieve maximum efficiency in MIG-MAG-welding. State-of-the-art arc control and FullProcess equipment ensure optimal results for a wide variety of materials and projects.

V-RoboTIG series

The V-RoboTIG series guarantees outstanding TIG performance with a high duty cycle. Perfect for automated welding (processes), it ensures stable and precise results with non-contact HF ignition and fast pulse technology.

Lorch Cobotronic

Lorch's Cobotronic software enables intuitive and user-friendly welding (processes). With practical modes and continuous updates, it is the perfect solution for achieving optimal welding results quickly and easily – always up to date.

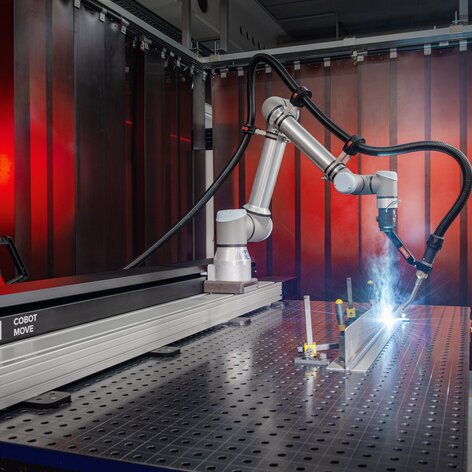

Cobot Move

The Cobot Move linear axis expands the working range of your cobot while offering absolute precision. Ideal for efficiently implementing larger projects and maintaining consistent welding quality across the entire working range.

Cobot Turn 100 A

The cobot Turn 100 A rotary tilt table allows you to position your workpieces perfectly. This not only ensures precise weld seams, but also saves valuable time and increases flexibility – even for demanding tasks.

SeamPilot

The SeamPilot from Lorch eliminates the need for complex programming. It automatically detects and tracks the weld seam, saving you time and ensuring perfect results even with high tolerances. The ideal companion for complex welding applications.

Speed welding (processes)

Lorch speed welding processes offer a significant increase in welding speed and seam quality. With greater penetration and improved appearance, the welding (process) becomes easier, safer and significantly more productive.

Experience the Cobot Welding World!

Take the next step into the future of welding.

Would you like to experience the cobot digitally, conveniently and without any effort? Or are you ready to test the system yourself? Whichever option you choose, you are in control and can get to know the cobot in the way that suits you best.

DIGITAL COBOT DEMONSTRATION.

Conveniently on screen.

Would you like to experience the advantages and possibilities of Lorch Cobot Welding World digitally?

Book your free online demonstration now and receive personalised advice from our cobot specialists. Gain practical insights and learn how our cobot solutions can optimally support your specific applications. Flexible, convenient and efficient – right on your screen.

RENT A COBOT.

Test our Lorch Cobot Welding World.

Increase your production capacity quickly and at predictable costs.

Rent a Lorch Cobot Welding Package and test it extensively before making a purchase decision. This way, you can ensure that the Lorch Cobot meets your exact requirements. In addition, renting is an ideal solution for short-term capacity bottlenecks and a shortage of skilled workers. It enables you to respond quickly and flexibly to changing market and economic conditions without entering into long-term financial commitments.

Got curious? Ask for your individual offer today at: service@lorch.eu.

The basis for your welding automation.

Configure the Cobot for your individual welding tasks.

Here you will find the appropriate contact option for your enquiry.

How to proceed:

Please select a category for your enquiry and try to describe it as accurately as possible. This will enable us to ensure that your enquiry ends up in the right hands and is processed as quickly as possible.

You can either give us a call or fill out the contact form below.

Contact:

+49 7191 503-0

info@lorch.eu

Availability:

Mon-Thu 08:00 - 16:30

Fri 08:00 - 15:00

* mandatory

Downloads

Would you like to learn more about Lorch's Cobot Welding World? Our brochure contains comprehensive information on how our cobot solutions can make your welding (process) more efficient, flexible and future-proof.