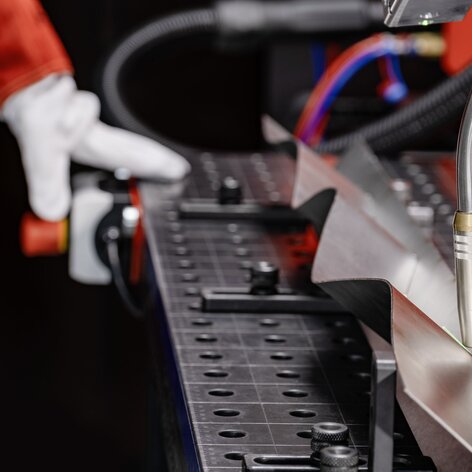

The autopilot for Cobot welding.The Cobot SeamPilot.

The SeamPilot will find, detect, and track the weld seam – even with high tolerances.

Programming complicated weld seams? Time-consuming Cobot teaching? Where conventional programming requires specification of all paths before the Cobot can track them, the SeamPilot will find its own path. A rough starting point is all it takes. Everything else will be done by the autopilot independently. It even produces some beautiful weld seams.

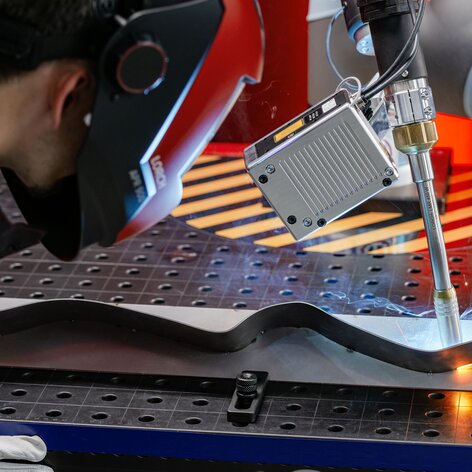

Welding at the push of a button.

All the SeamPilot needs for its work is a rough starting point – simply place the laser in the desired position and get going. The laser will find its own weld seam, track the seam course, and guide the torch precisely.

Overview of the advantages.

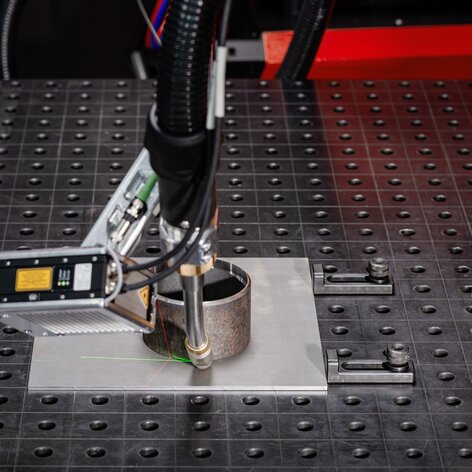

- Unbelievably simple programming: Only a rough starting point needs to be specified. SeamPilot will find the further course of the weld seam.

- No teaching: Automatic implementation of the pre-defined torch position and angle.

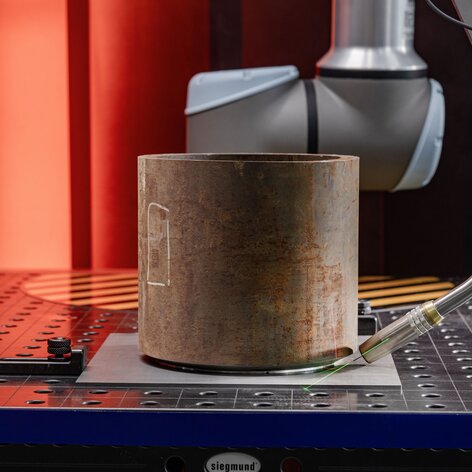

- Weld seam length specification: Via weld seam length, rough end point, or automated recognition.

- Even for complex demands: Easily mastering outer edges or multiple weld seams in sequence on the same part.

- Adaptable: Flexibly adjustable parameters for optimised welding results.

Downloads.

Would you like to learn even more about the Cobot SeamPilot from Lorch? Technical data as well as details on application and equipment can be found here: