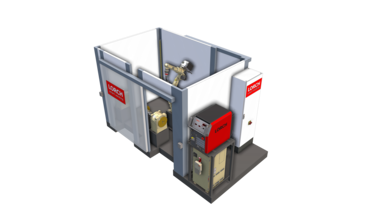

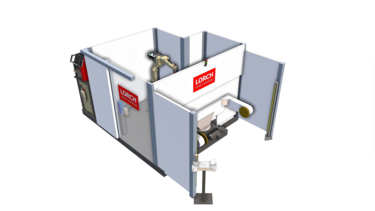

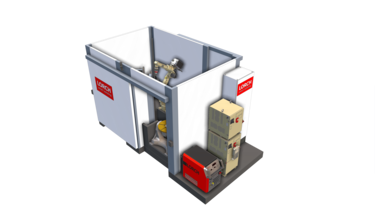

The best of both worlds.

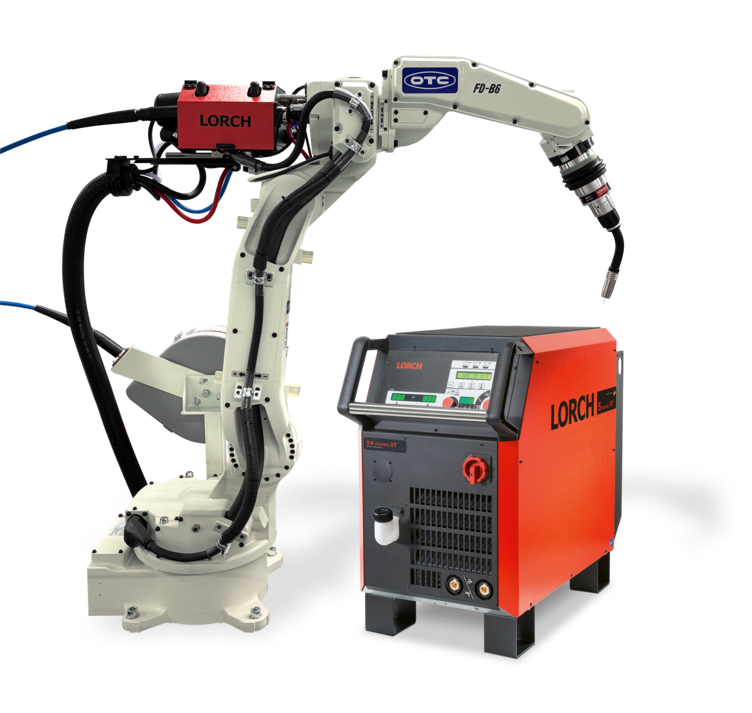

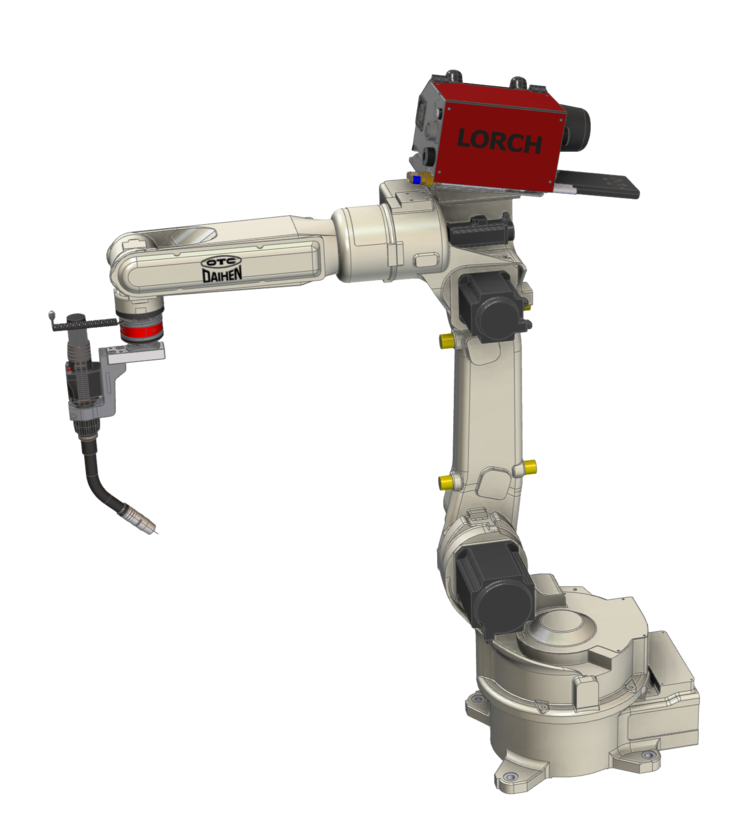

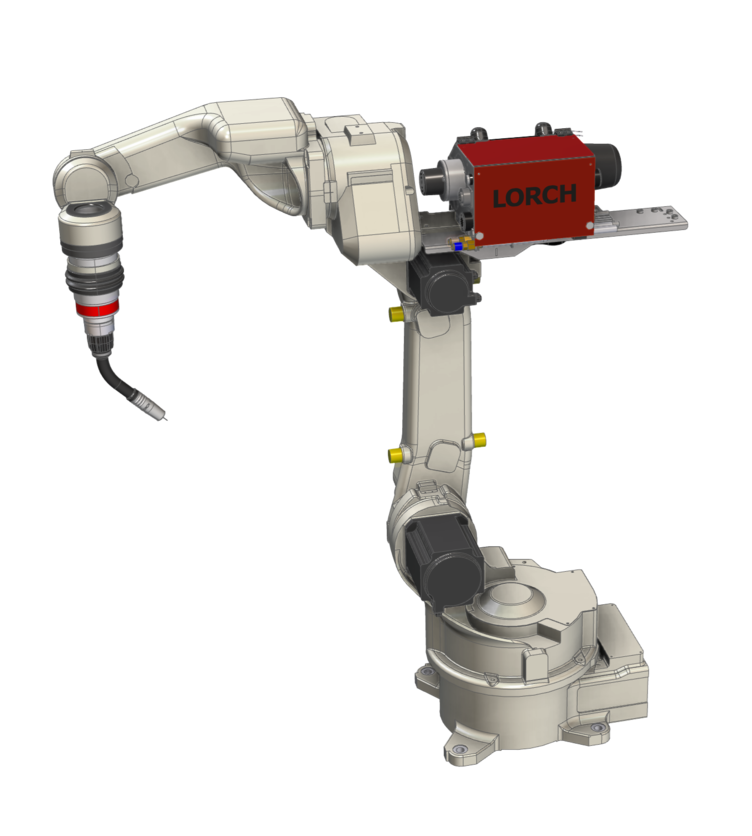

With the precise movements of the OTC Daihen welding robot and the innovative Lorch welding technology, entire production series are welded with maximum quality.

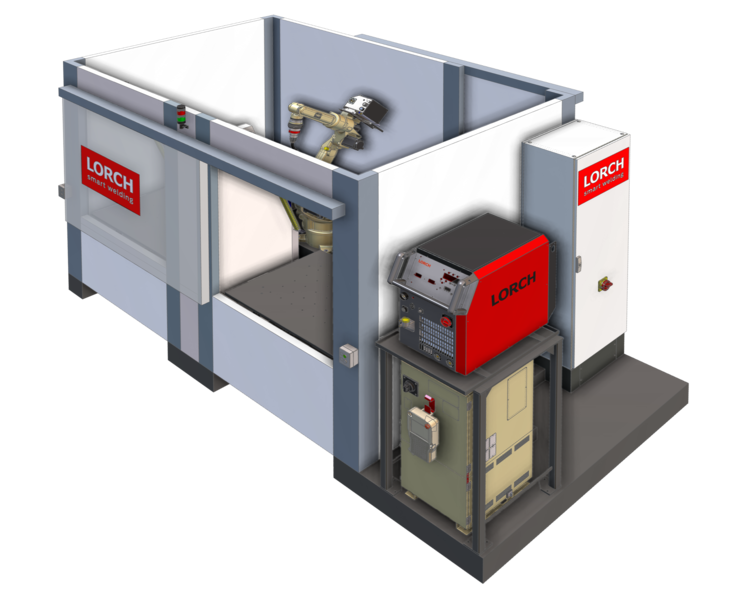

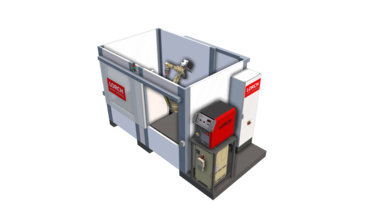

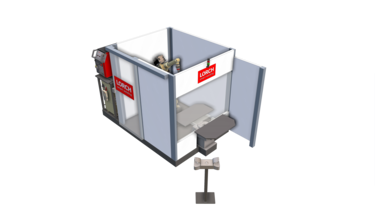

Maximum safety.

The compact welding cells form a closed, CE-compliant system. The numerous safety features ensure the best possible protection for the user.

Plug & Weld.

The welding cells are customised and delivered ready to use. Simply plug in and start welding.

Increased productivity.

Series production around the clock? The welding cells from Lorch and OTC are ideally suited for high-volume production. Thanks to the efficient workflow and exact reproducibility of the seams, productivity is significantly increased.