Pure efficiency.

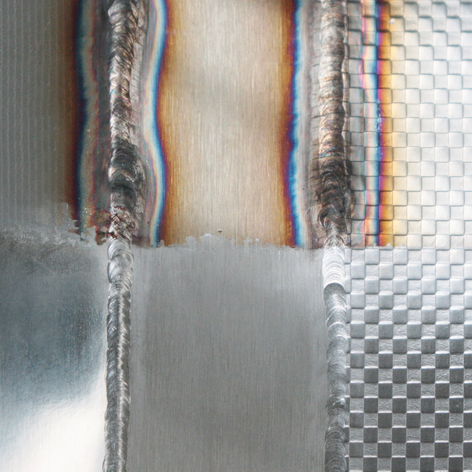

Millions of small arcs at the ends of the carbon fibre brushes remove all impurities on high-alloyed stainless steels and even on non-ferrous metals such as copper in the blink of an eye. A second work step to passivate the weld seam is not necessary.

No hazardous substances.

The EC-Clean 1000R cleans with the power of arcs without using any toxic pickling chemicals such as hydrofluoric or sulphuric acid. Only non-toxic electrolytes that are also used as the food additive E338 are used for this.

Cleaning, polishing and passivation in a single step.

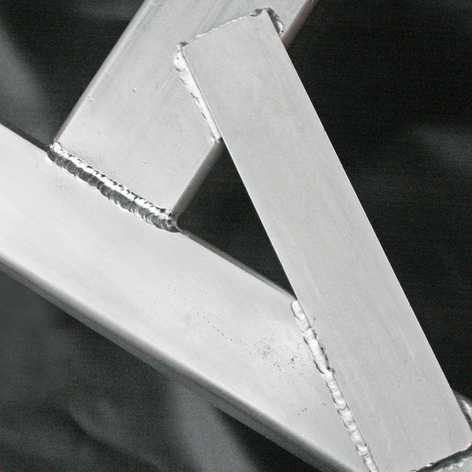

- Cleans thoroughly and quickly even in corners and edges

- Polishes the workpiece until its surface is as smooth as glass

- Passivation protects the workpiece from corrosion

- Perfectly non-toxic electrolytes

Signing of texts and motifs.

- Dark-signing of stainless steel by oxidation.

- Light-signing of aluminium by material removal

- Durable and resistant to chemicals or abrasion

- Long-term stencils can be used up to 5,000 times