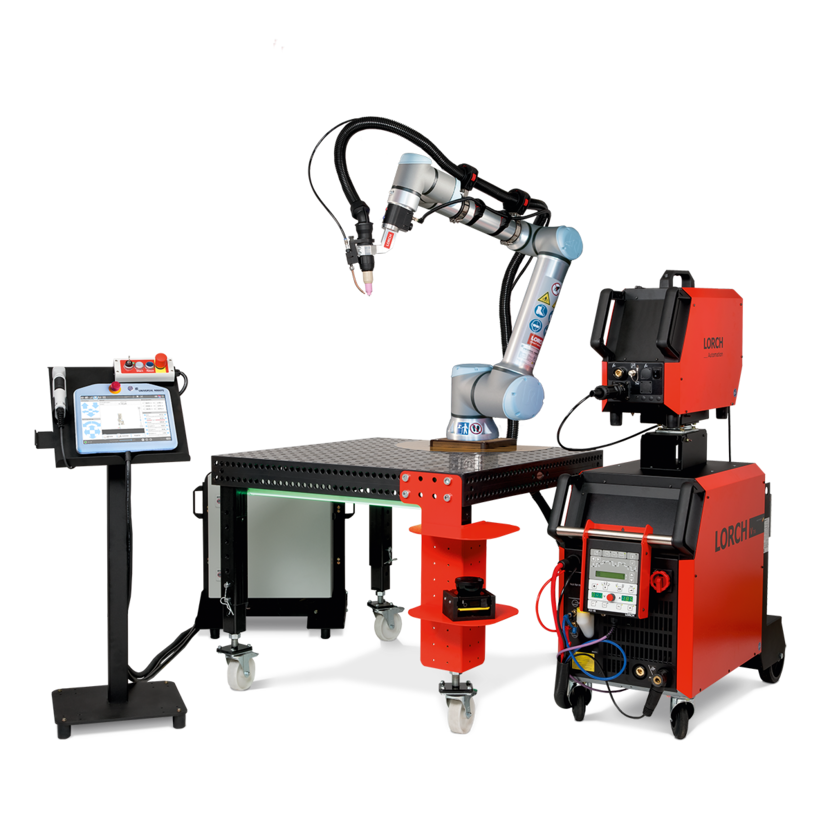

Simple programming.

The free-drive function allows welders to point the Cobot manually to where it is to weld, including intermediate points and sections. Operators can then perform their tasks precisely with the robot’s help. The optional multifunction flange also permits programming right on the 6th robot joint to avoid unnecessary paths.

Safe and flexible.

The laser and function button safety concept keeps the operator out of the robot arm movement radius while welding and ensures a smooth weld. As a result, the Cobot does not need to be enclosed and welding goes flexibly.

Top results.

The digitally fully integrated cold wire feed permits precise and reliable cold wire feeding during welding operation. This, in combination with the Cobot, ensures easy feeding and reliable results without spatter.

Highest TIG efficiency.

The V 30 AC-DC TIG power source included in the package is perfectly suited for automated operation due to its optimised ignition properties. The integrated fast-pulse technology also ensures maximum efficiency in TIG welding automation.

The Cobot Move linear axis.

The Cobot Move linear axis is THE supplement for enlarging the Cobot workspace to up to 4.5 m. The Cobot remains highly precise thanks to the high-quality ball screw drive installed in the Move linear axis in order to ensure a consistent welding quality across the entire workspace.