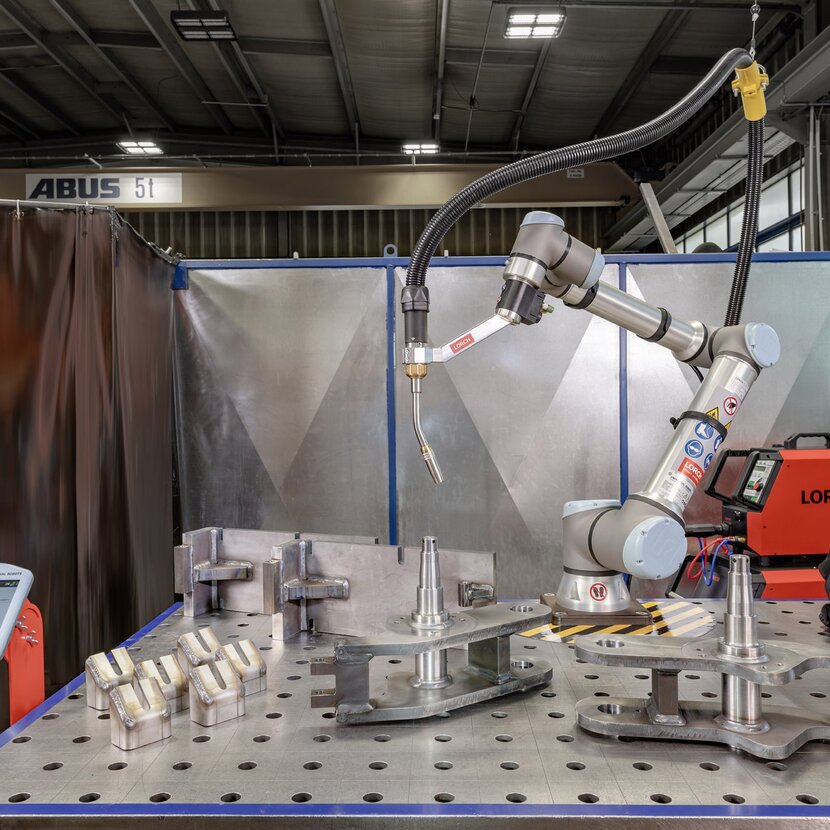

Say farewell to skills shortages, cost pressure, and technology gaps.

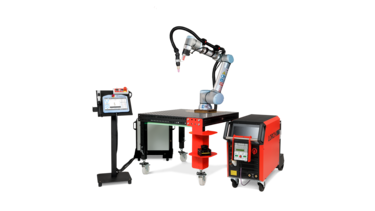

You can relieve your employees and increase the productivity and profitability by optimising use of your human resources with the Lorch Cobot Welding Solutions. Reduce scrap, rework, and costs by consistent performance and reproducible results of the highest quality. Stay future-proof and position yourself as an attractive employer for young, tech-savvy talent with this practical step towards Industry 4.0.

Reproducible perfection.

The Cobotronic software enables you to have your welding parameters determined automatically after entering the material, wire, gas, and throat thickness a to give you optimal welding results every single time.

Always the matching innovation.

The package comprises all the innovative Lorch MIG-MAG Speed processes. This means that you will always have the optimal welding process available to maximise both productivity and quality. TwinPuls XT, for example, produces attractive TIG-look weld seams with unparalleled efficiency.

Full power.

The high-quality, high-performance S series included in the MIG-MAG package enables you to weld virtually anything at the highest efficiency with its high-end inverter technology, lightning-fast control technology, precision feed, and complete full-process equipment.

Practical ergonomics.

The optional multi-function flange permits easy free-drive programming on the 6th robot joint as well, rendering tack weld placement and torch positioning ergonomic and efficient.

The Cobot Move linear axis.

The Cobot Move linear axis is THE supplement for enlarging the Cobot workspace to up to 4.5 m. The Cobot remains highly precise thanks to the high-quality ball screw drive installed in the Move linear axis in order to ensure a consistent welding quality across the entire workspace.