Case: Jorado Maschinenbau GmbH Capacity increased, welders relieved.

Jorado is welding much faster thanks to the latest Cobot solution.

Founded in 1961, Jorado Maschinenbau GmbH has developed an excellent reputation as a full-service provider with core competences in turning, milling, welding, and assembly. Precision, innovation, and flexibility are the three pillars of the medium-sized enterprise with more than 85 employees today. State-of-the-art machinery – metal processing is using CNC machines exclusively – is part of the corporate philosophy just as much as comprehensive training of young talent. The company has recently been using a welding Cobot by Lorch, not merely with the purpose of creating important new production capacities but also to compensate for the ever-increasing lack of specialists by using the automated welding solution. The welders are relieved from repetitive, exhausting welding tasks and are able to focus fully on their core competence.

Overview of Jorado Maschinenbau GmbH.

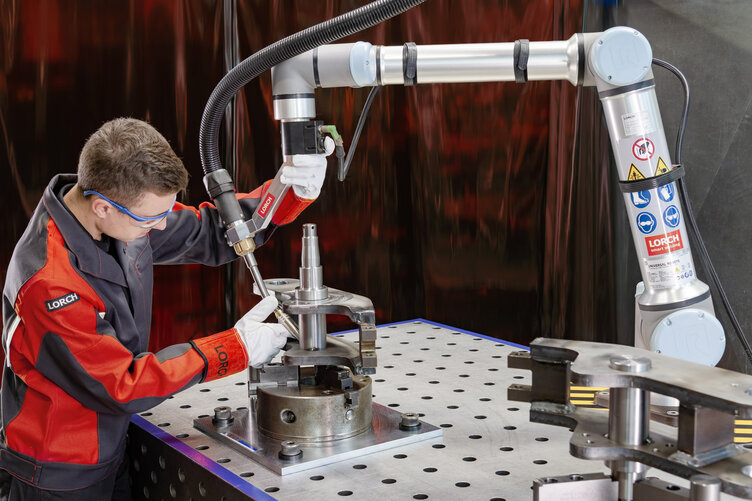

The large working radius of the UR10e Cobot from the Lorch Cobot Welding World and the Smart Copy programming function offer ideal prerequisites for smooth production sequences.

The innovative multifunctional flange and three freely assignable buttons permit direct integration of the practical additional Quick-Points feature for speedy teaching of parts on the Cobot.

Easy-to-operate, practical additional features, great reach.

An ideal solution for efficient welding.

The Cobot can be used quickly and easily thanks to the intuitive operation of the Cobotronic software. Programme features additionally integrated in the software render welding with the Cobot even more efficient: The Smart Copy function transfers already-programmed welding processes to parts of the same build in the work area to allow immediate welding in series production. The Quick-Points function on the multifunctional flange makes it possible to directly take over points along the path and welding commands by the push of a button in order to teach parts very quickly. The Cobot UR 10e, the latest model by Cobot market leader Universal Robots, offers further advantages by its faster movement speed and a reach expanded to 1,300 millimetres. Combined with Smart Copy, it can weld several clamped parts in series at once on a correspondingly sized worktable. The practical multifunctional flange right at the Cobot head with three freely assignable buttons also permits execution of programming steps right on the robot. Its ergonomically shaped handle enables relaxed positioning of the Cobot in Freedrive.

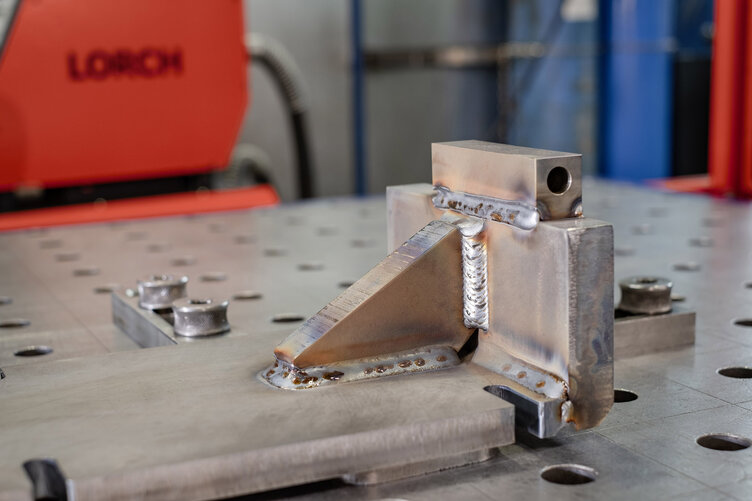

Production of machine parts requires absolute precision. The Cobot solution by Lorch warrants the highest quality throughout even at high piece numbers.

The Lorch Cobot Welding Package MIG-MAG: Get going now!

Cobot welding means collaborative robot welding for medium-sized companies. The MIG-MAG edition of the Lorch Cobot Welding Package is the ideal tool for economical welding automation in small and medium series production. What are you waiting for? The Lorch Welding Package MIG-MAG lets you start automating your welding production right away.

Downloads

Do you want to learn more about the Lorch Cobot Welding Package MIG-MAG? Technical data as well as further details on application and equipment can be found in the data sheet, and additional information is provided in the brochure: