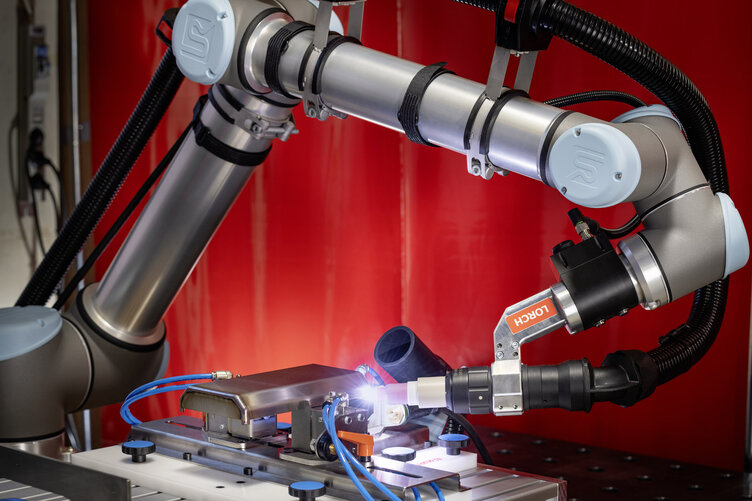

Cobot welding.Robots and people weld hand in hand.

The simplest solution for your welding automation.

Cobot welding is fast, flexible and economical.

Collaborative robot welding, or cobot welding for short, is ideal for companies looking to automate their welding processes. With lower investment costs and high flexibility, this technology is perfect for small and medium-sized series. Cobots enable direct collaboration with the welder – without protective cells.

The challenges for businesses of all sizes.

Skills shortage, cost pressure and technology gaps.

Are you having difficulty finding qualified welders?

Are you under increasing cost pressure while simultaneously facing higher quality demands?

Are you looking for ways to position your business technologically for the future?

Many companies, from SMEs to large industrial firms, face these challenges. In order to remain competitive and ensure consistently high quality, skilled workers must be deployed efficiently and work processes optimised. Especially for small and medium-sized series, it is crucial to maintain flexibility in production volumes while adhering to high quality standards.

Cobot welding offers the solution to successfully master these challenges.

Compensate for skills shortages.

- Time and physical relief for skilled workers: Welders programme the welding task, operators carry it out with the cobot

- Increased productivity through simple operation and high flexibility

- Efficient and reliable achievement of the required production volume

Ensuring quality, cutting costs.

- Consistent and reproducible welding quality – 365 days a year

- Very high quality results: less rework, less waste

- Significant cost savings thanks to consistently high quality

Keeping up with the times.

- A simple step towards Industry 4.0

- Highly regarded as an attractive, forward-looking and ergonomic employer

- Rapid return on investment

Lorch Cobot Welding World.

Whether MIG-MAG or TIG.

Would you like to automate your welding production with a cobot?

Lorch Cobot Welding World offers you the perfect complete package!

The flexible modular system offers a customised complete solution, combining

- high-quality robot technology from the cobot market leader Universal

- innovative welding technology from Lorch

- intuitive Lorch Cobotronic operating software

- and a comprehensive range of services with the best professional support.

For both highly efficient MIG-MAG applications and highly demanding TIG welding tasks.

The cobot guide:

For greater efficiency in your welding operations.

Are you interested in cobot welding and would like to learn more about its advantages and applications? Our free cobot guide provides detailed information about the use of collaborative robots in welding technology.

Find out how cobots drive automation and productivity in companies and why they are ideal for flexible series production.

Download the PDF now and deepen your knowledge of cobot welding solutions.