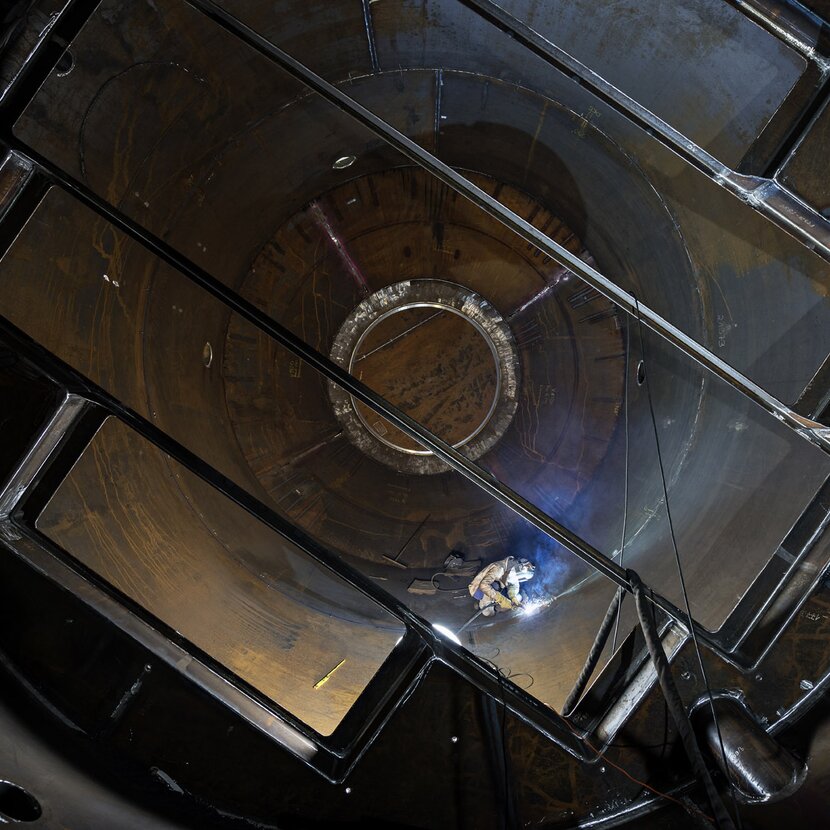

Best welding properties.

Cutting-edge processor technology ensures optimum interaction of all parameters and components involved in the welding process. Peak duty cycles and maximum productivity are achieved in the scope of this.

Extra performance by MIG-MAG Speed processes.

All Lorch Speed processes are available for the S3 to achieve the most diverse areas of application: The included SpeedPulse XT, TwinPuls XT, SpeedArc XT processes, and the optional SpeedUp, SpeedCold, and SpeedRoot upgrades make welding faster, improve quality, and reduce spatter in any welding job.

Sophisticated industrial housing.

Robust metal housing, low gas cylinder holder, crane rings, torch holder: S-series welding equipment is designed and built for years of support for your welding challenges.

Future-proof.

The S3 can be upgraded, which means that the process equipment of a welding system can be customised to match new requirements at any time. This keeps the user flexible and future-proof.

EN1090-compliant package.

Save some time- and cost-intensive individual tests of your welding results! The enclosed Lorch WPS booklet contains independently certified welding instructions of all relevant standard welding procedures for easy EN1090-compliant welding.

Energy efficiency at full power.

The Lorch S3 combines top performance with efficient inverter technology and a stand-by function. This reduces costs while achieving perfect welding results.

Country-specific product variants.

Country-specific product variants are available for this Lorch welding unit. These may differ in the mains supply, the mains plug or other product features required for the country. You want to know more? Contact your local Lorch partner.