Optimal integration.

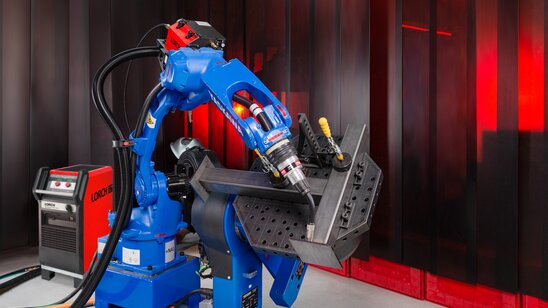

Robo-MicorMIG can be integrated into different automation systems from any common robot manufacturer quickly and easily with its digital fieldbus protocols and two available analogue interfaces.

MicorBoost-technology for perfect welding results.

The innovative and patented Micorboost technology ensures maximum performance and top quality to enable perfect welding for any welder. The unit stands out with optimal welding properties in any work with metal sheets, medium, or heavy steel. The Robo-MicorMIG achieves outstanding welding results on steel, stainless steel, and aluminium with mixed gas and under CO2 alike.

Quality management made easier.

The NFC authorisation concept also permits precise access and authorisation control for higher quality in management and overview.

Future-proof with upgrade concept.

The system offers full upgrade capacities and allows addition of welding procedures, welding programmes as well as functions that make work easier at a later time with its NFC function. New options can be installed offline and without requiring any external support, allowing system expansion at any time to include precisely those functions that are required for the welding tasks at hand.