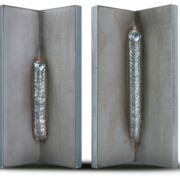

Perfect welding results.

The innovative and patented Micorboost technology maximises power and the voltage reserve in the arc, optimising welding properties for all sheet metal as well as medium and heavy steel work with mixed gas or under CO₂ alike. Outstanding welding results on steel, stainless steel, and aluminium are the result.

Compliant and combinable.

Easily weld EN1090 compliantly thanks to the WPS booklet. Save some time- and cost-intensive individual tests of your welding results. The booklet contains independently certified welding instructions for all the relevant standard welding procedures. The MicorMIG series also keeps your parameter sets conveniently available via an NFC job card.

Future-proof & flexible.

Erweitern Sie Ihre Anlage jederzeit um genau die Funktionalitäten, die Sie benötigen: Dank der NFC-Funktionalität ist die MicorMIG voll upgradefähig. Das bedeutet, Sie können zusätzliche Schweißverfahren, Schweißprogramme sowie arbeitsvereinfachende Funktionen mit NFC-Karten jederzeit nachträglich aufspielen – offline und ohne externe Unterstützung.

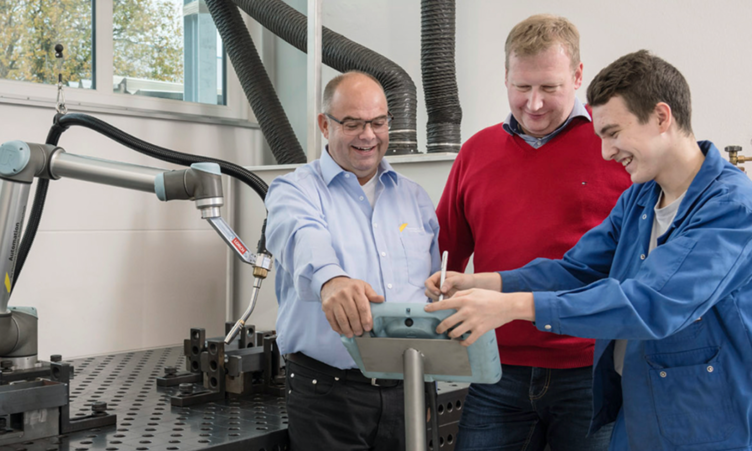

Quality assurance with the authorisation concept.

Expand your system at any time with the precise functions you need: The NFC function makes the MicorMIG fully upgradeable, allowing you to subsequently install additional welding processes, welding programmes, and functions to facilitate work with NFC cards at any time, offline and without needing any external support.

Outstanding price-performance ratio.

The MicorMIG offers an easy switch to a fully adjustable welding system. Profit from the optimal welding properties of the MicorMIG at an excellent price-performance ratio. It simply is the better alternative to the conventional transformer system.

Energy efficiency by technology.

The MicorMIG combines robust performance with efficient inverter technology and a stand-by function. This reduces costs while achieving perfect welding results.