Lorch SpeedUP.The quick and simple path to vertical up welding.

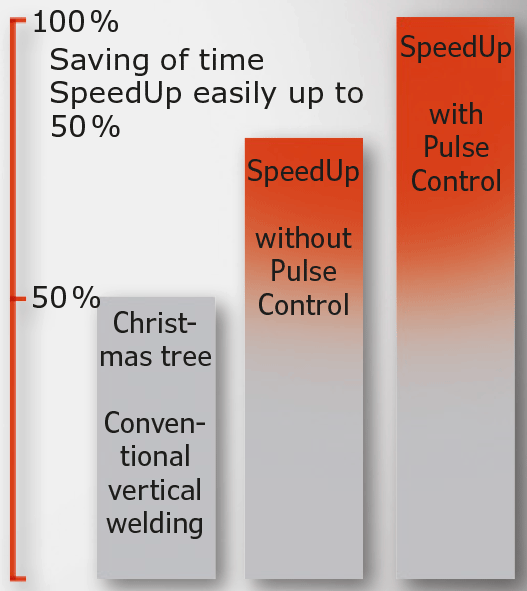

Vertical welding? It used to be difficult. The perfect vertical weld used to be the “distinction”. The triangular hand movement of the hand required, with gently heating material without letting it cool off too far, a secure grip on the root, and careful support used to be a technique reserved for experts. These men were called X-mas tree welders with a certain reverential tone. However, the technique was just as slow as the growth of trees, and deadline pressure often an unsurmountable obstacle.

It was nothing but logical for our engineers to look into ways to simplify this process.

The “simple” vertical weld.

The secret is in combining two processes, or rather: two arc phases. One is the “hot” high-current phase with high energy input for best heating of the material. Perfect control technology ensures a smooth transition to the “cold” phase, virtually spatter-free. The reduced energy input ensures reliable penetration, precisely sized weld filling and a near-optimal throat thickness a. Even welders in training can master the SpeedUp in no time at all.

High power.

If you have knocked a deep hole in a wall for a single thin cable in it, you will find that it takes a long time to close the whole thing up again. This is what used to be the situation in vertical welding. SpeedUp by Lorch is a lot more precise. It virtually only produces a narrow, precise wall joint that closes up again in no time at all. The throat thickness a required is applied precisely for sheets of up to 12 mm.

The Lorch P-series SpeedUp is already 60-80% faster. This is a huge leap forward for everyone who has to do vertical welding here and there. SpeedUp with PulseControl allows up to 100% faster vertical welding with the S-series now as well, for twice the working speed that is currently common.

Advantages of the SpeedUp:

- Automation/Manual welding:

Continuous movement in the mechanised torch guidance is very good for automation/very simple manual torch guidance - Fillet welding

Optimised for fillet welding (FW) in PF (vertically up) welds, can also be useful in other weld positions - Even heat application

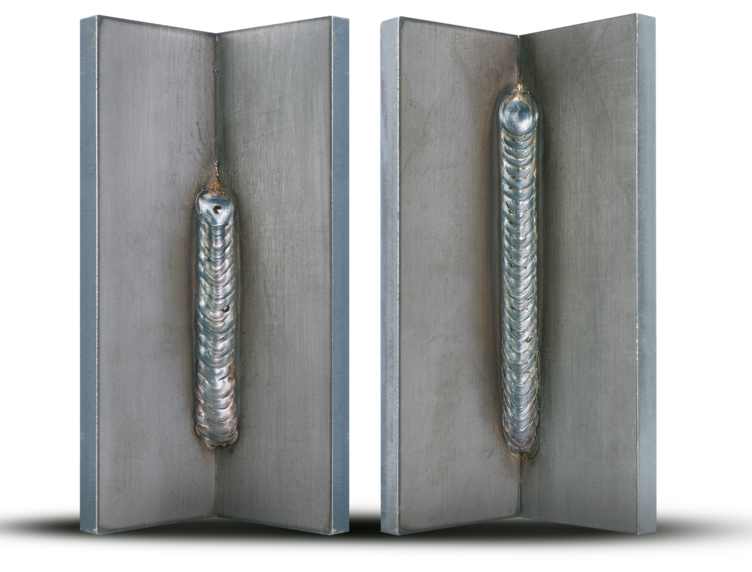

Penetration and material bond appear even and slightly wavy - Even, slightly scaly seam surface

Narrower weld seam than conventional triangular FW+PF movement;

Avoids errors that may occur with conventional triangular movement

Downloads

All relevant facts and figures as well as additional information can be found in our

Your welding equipment for SpeedUp:

- S series: SpeedUp optional

- P series: SpeedUp optional

- MicorMIG and MicorMIG Pulse: SpeedUp optional