Case: GIPO AG Welding tractors solve issues with longer seams at GIPO.

Lower stress at significantly higher productivity and quality.

Swiss company GIPO a leading manufacturer of track-mounted, fully hydraulic rock crushers. The chassis of these gigantic machines are made almost entirely of S 355 sheet steel. Load-bearing elements may sport sheet thicknesses of up to 30 millimetres, with weld seams subject to extreme forces when the minerals are crushed.

As a result, the many, extremely long weld seams in many areas of the chassis must have the highest quality. The company uses the Lorch Trac Wheel Pro welding tractor for particularly long and critical weld seams. Not only does it increase safety, it also significantly reduces costs.

Overview of GIPO AG.

Long, high quality weld seams are

The tractor advantage:

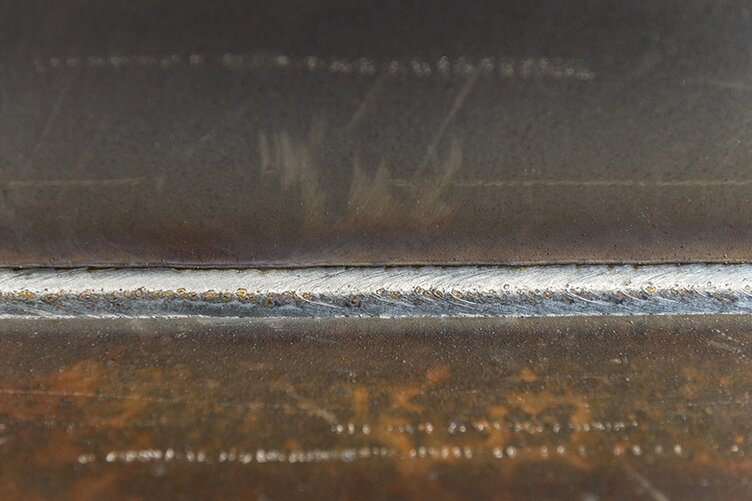

A perfect weld seam from start to finish. The optimal weld setting prevents spatter and eliminates time-consuming rework.

Textbook weld seams.

The detailed view also shows how even the weld seam performed by the tractor is.

The entire welding solution as used by GIPO:

Lorch Trac Wheel Pro with the S-series, SpeedPulse XT and SpeedArc.

The Lorch Trac Wheel Pro is a highly portable and easy-to-program welding tractor, designed for particularly demanding longitudinal and curved seams and capable of handling weld seams with large seam volumes. GIPO AG uses the powerful S series from Lorch as the welding current source and works with the innovative SpeedPulse XT and SpeedArc welding processes.

Time and resource saving work.

Reproducible quality and no rework of weld seams required.

The tractor has already proven its worth in just a few months. The machine is two or three times faster than manual welding, with a consistently excellent weld seam. Welders at GIPO used to have to start over at least three or four times in order to complete the weld seam, which is more than 4.5 metres long, in particular for very difficult weld seams, such as the one on the box for the mobile chain drive. Grinding of the weld seam and the processing of the transitions consumed valuable working time. The tractor creates an uninterrupted weld seam of the highest quality from start to finish. This also eliminates the otherwise very time-consuming rework.

Another advantage is that the set and stored data allow reproduction of the weld seam on other chassis again and again at a consistently high quality. This saves an enormous amount of time and also extremely increases safety.

To the perfect weld seam in just a few steps

Set up the unit, adjust the values, and start welding. A magnet allows easy fastening of the tractor, while a high-performance motor ensures a precise welding speed.

Trac WL-series: Welding tractors for partial automation.

High-quality and reproducible welding of longitudinal and curved seams on magnetic substrates with welding tractors from Lorch. Mobile. Compact. Flexible.

Typical applications include long supporting structures such as in trailer and rail vehicle construction, shipbuilding, and large containers such as truck, oil, and water tanks. Even high seam volumes and a larger throat thickness a are no problem with the powerful Pro version of the series. The battery-powered version of the Trac WL series is ideal for welding containers.

Downloads

Do you want to learn more about the Lorch S-series? Technical data as well as further details on application and equipment can be found in the data sheet, and additional information is provided in the brochures: