EN1090-compliant package.

Save some time- and cost-intensive individual tests of your welding results! The enclosed Lorch WPS booklet contains independently certified welding instructions of all relevant standard welding procedures for easy EN1090-compliant welding.

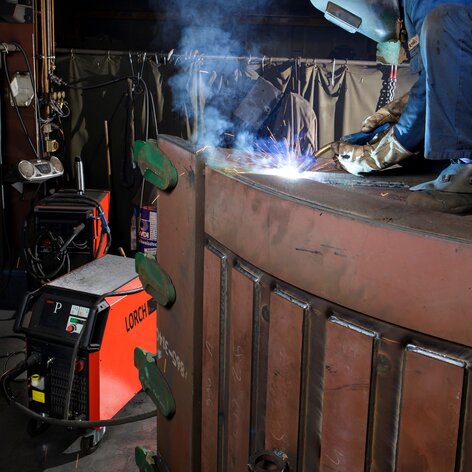

Energy efficiency at full power.

The Lorch P-series combines top performance with efficient inverter technology and a stand-by function. This reduces costs while achieving perfect welding results.

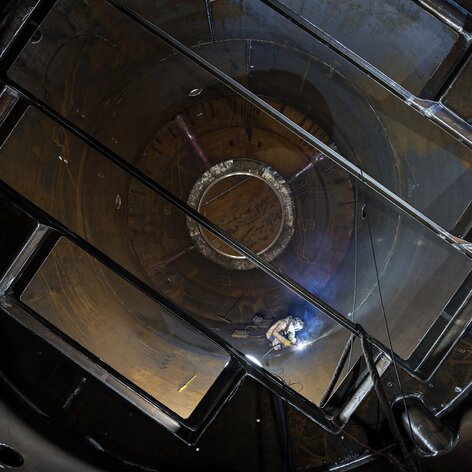

Extra performance by MIG-MAG Speed processes.

The P-series has Lorch Speed processes that create the most diverse areas of application. The included processes, as well as the optional upgrades will let you weld more quickly and at higher quality.

Learn more about the Lorch Speed processes

Operating modes can be optimised individually.

Quatromatic technology avoids cold laps at the welding start and ensures optimal end crater filling. Save up to three individual parameter settings and call them up again easily in 4-stroke operation via the torch button.