MIG-MAG- WELDING.The versatile high-performance welding process explained.

What makes MIG-MAG welding so special?

MIG-MAG welding or metal inert gas welding is divided into metal inert gas welding (MIG) and metal active gas welding (MAG).

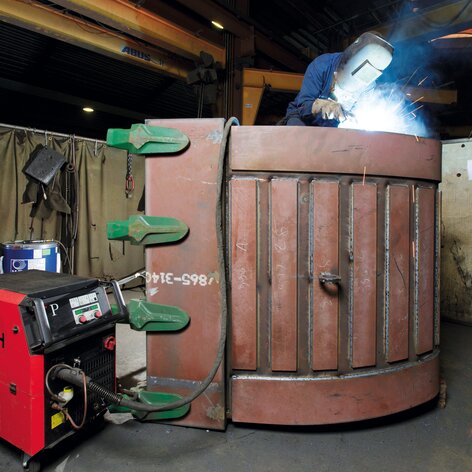

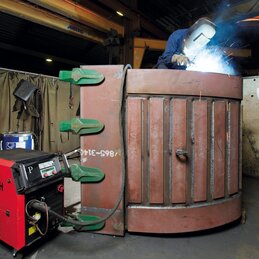

The high welding speed, minimal rework and low distortion make MIG-MAG welding processes extremely economical. A special weld seam strength, the excellent thin sheet properties and the simple and safe handling for steel, aluminium and stainless steel ensure that MIG-MAG welding is considered to be universally applicable.

Due to these enormous advantages, MIG-MAG welding is the most widely used welding process today.

How does MIG-MAG welding work?

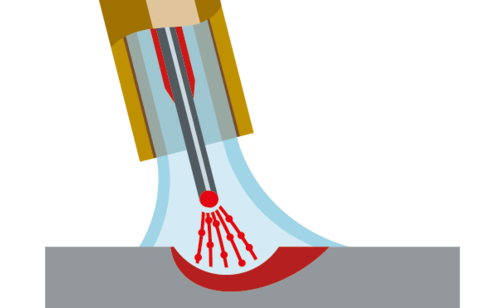

In MIG-MAG welding, the electric arc burns between the melting, automatically fed welding wire (=electrode) and the workpiece.

A separately added gas flows through the gas nozzle and protects the arc and the welding zone from oxygen in the environment. This prevents oxidation on the weld pool and the welding wire. However, the shielding gas and the welding wire must be adapted to the base material.

Which materials and gases are suitable for MIG-MAG welding?

Aluminium and aluminium alloys.

- Process: MIG

- Wire electrode: according to the material to be welded

- Shielding gas: Ar, He or mixtures

General structural, boiler and tube steel.

- Process: MAG

- Wire electrode: SG 1-3

- Shielding gas: mixed gases (argon/CO2 or CO2)

Stainless steel and high-alloy steels.

- Process: MAG

- Wire electrode: according to the material to be welded

- Shielding gas: mixed gases (argon/CO2 or argon/O2)

Advantages and disadvantages of MIG-MAG welding.

Advantages:

- Easy to learn

- High welding speed

- Minimal rework and distortion

- Low costs for additional material

- Excellent thin sheet properties

- Very well suited for mechanised and automated welding

Disadvantages:

- Inert gas supply can be disturbed by draughts

- Susceptible to rust and moisture

- Not suitable for aseptic and food-safe applications

Our solutions for MIG-MAG welding.

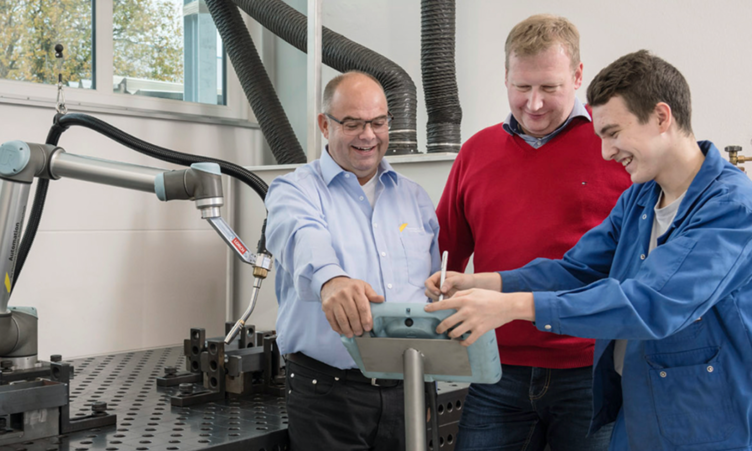

Always the best advice: close, personal and honest.

Are you interested in a Lorch welder with special suitability for MIG-MAG welding, but are not sure which model is right for you or have other queries? Use the Lorch partner search to easily find a competent contact person near you and get personal advice.