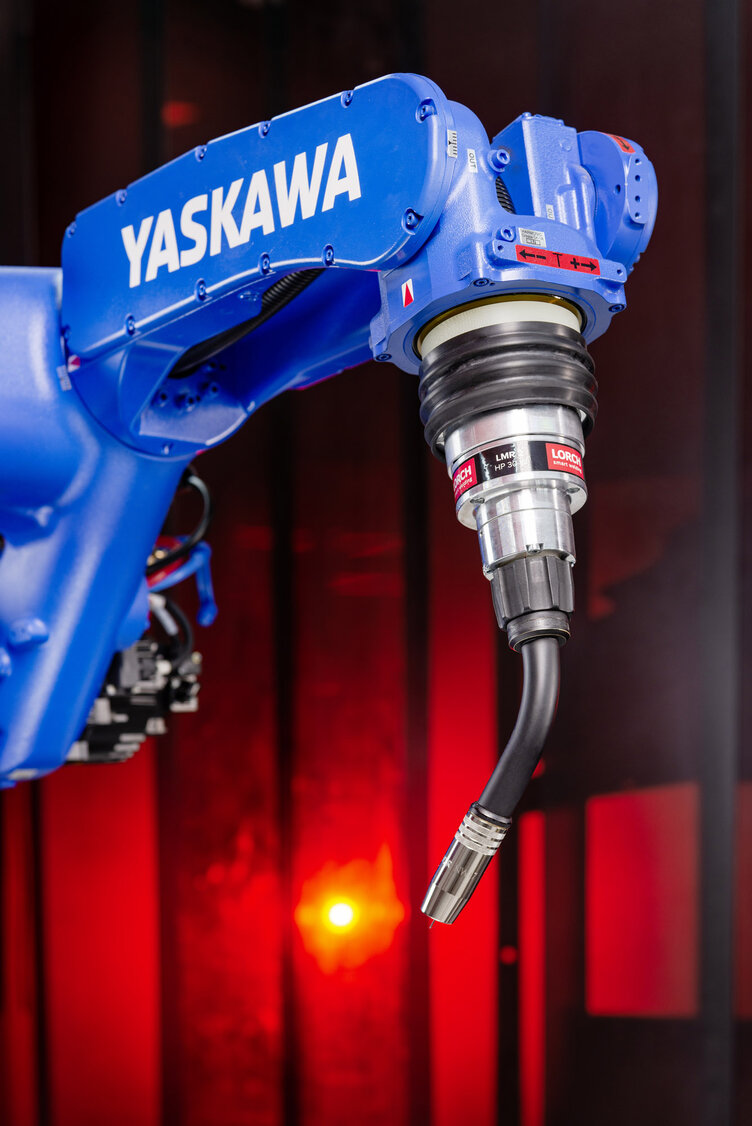

Universal Lorch interface.

The interface connects the robot to the power source. It is perfectly matched to both components, simplifying programming and control of the power sources and reducing susceptibility to errors to provide greater safety and increased quality as a result.

Speed processes.

Innovative Lorch welding processes renders welding much easier and faster, reducing production costs in the long term.

Seam tracking.

Digital seam tracking makes it possible to ensure that welding has been performed correctly, no matter the type of control and arc. This makes operation more comfortable and expands your welding options.

Performance & service life.

The Lorch product and torch range, developed specifically for this automation solution and optimised based on the system, is perfectly matched to a wide range of applications for perfect welding performance and longer service lives of the wear parts.

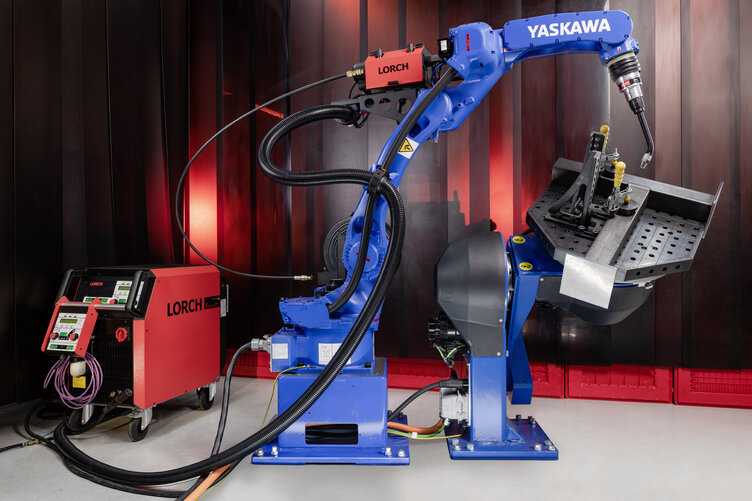

Cooperation & service.

Close cooperation between Yaskawa and Lorch ensures smooth processes in delivery, commissioning, and service. A fixed contact can provide quick help.

Plug & weld

Automate your welding production in the blink of an eye and profit from your welding work right away with the quick, simple, and automatic solutions from Yaskawa and Lorch.