The MicorBoost technology.

Welding is clearly improved by MicorBoost technology.

MicorBoost technology renders welding units even lighter and more compact. Hard as it seems to believe, it increases power output at the same time with the method covered in our patent EP 191 3680 B1.

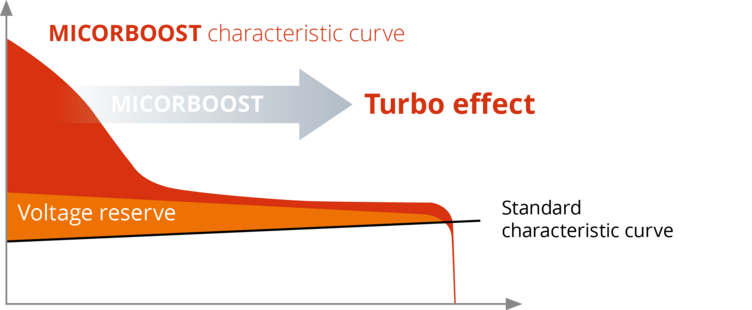

We are happy to explain it with a practical example as well: Conventional welding inverters have relatively low voltage reserves. This means that an arc that destabilises in MMA welding cannot be stabilised again by a conventional inverter, causing the arc energy to drop for a moment and reduce the average arc performance.

Just as when you have to briefly stop at the red lights all the time, it reduces your average speed.

MicorBoost technology offers enormous voltage reserves, avoiding the drop or shortening it considerably and increasing the average arc performance as a result. It feels like a turbo on a car when welding as you can quickly race across the light before it turns red or, if you have to stop anyway, you will be back to speed again very quickly afterwards.

This voltage reserve has another, equally important effect as well in its virtually perfect welding behaviour. The arc start is reliable, saturated, and makes work much easier even at rusty material. There’s no need to tap the electrode until the arc eventually ignites. Experience a new, extremely stable and controllable welding quality and stay in control even when you lengthen the arc.

MicorBoost inverter technology:

Inverters with MicorBoost technology build a high voltage in particular at the critical, lower current levels, to ensure maximum stability

World champion lightweight

Every kilogram of weight that you don’t have to carry is important at the construction site.

Our welding inverters with MicorBoost technology are impressively light and compact.

Make life easier for yourself by literally reducing your workload and saving energy for the important things: Great weld seams.

The master of long distances

Mobile use often is a necessity since many workplaces are far apart. The MicorBoost technology increases the action range and allows welding on extension cables of up to 200 m or even on a generator with perfectly reliable ignition behaviour and without losing any quality.