Electrode welding.Location-independent. Easy to handle. Even subject to rough working conditions.

What makes electrode welding so easy?

Electrode or MMA welding is the simplest welding process, which is why it is very suitable for beginners. Nearly all weldable materials can be welded with rod electrodes and even constrained positions are no issue.

Since the welder is independent from shielding gases, this welding process is ideal for outdoor welding in wind and weather. On top of this, the welding units can be operated with lithium-ion batteries independently of a mains supply. Inverter welding units also offer outstanding welding properties that make them suitable for special electrodes.

How does Electrode welding work?

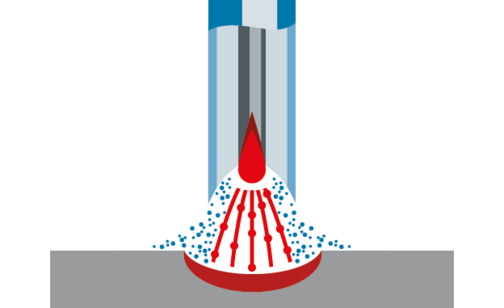

The electric arc burns between the workpiece and the melting electrode In MMA welding (or manual arc welding, stick electrode welding, or manual e-welding). At the same time, the electrode supplies the filler material.

How does Electrode welding proceed?

The rod electrode is clamped in the electrode holder for welding and guided along the weld by the welder. Its coating melts while welding, protecting the weld pool and the arc from ambient air by releasing gases and slag. The slag is removed once the weld pool has cooled down.

This welding process is easy to learn. In fact, MMA welding often is the first type of welding a welder performs in his training.

Almost all weldable materials can be welded with rod electrodes. This includes:

- Structural steel

- Boiler steel

- Tubular steel

- Cast steel

- Stainless steel

- Hard-facing steels

- etc.

Inverter welding units are particularly suitable for MMA welding. Their good welding properties also makes them well suited for special electrodes and for mobile use. They can now also be operated independently of a mains supply with lithium-ion batteries. Since they need no gas, they can be used for outdoor welding, even in windy conditions.

Advantages and disadvantages of Electrode welding.

Advantages:

- Easy handling

- Independent of the power grid and weather

- Relatively robust against contamination such as rust

- Welding of nearly any materials

- Low noise exposure of the welders

Disadvantages:

- Mechanisation not possible

- High smoke emission

- Low speed and high pre- and postweld times possible

- The electrode diameter is determined by plate thickness and welding position

- End craters and slag can become error sources

Our solutions for MMA welding

Always well-advised with close, personal, and honest support.

Are you interested in a Lorch welding unit for MMA welding but not quite certain of which model to choose yet? Do you have any other questions? The Lorch partner search will easily let you find a competent contact in your area to give you some personal advice.